The Xiegu G90 Junkbox Manpack

Executive Summary

Yep, still doing these summaries- your time is important, and you may decide to cut and run :)

1) The G90 needed an easy grab and go way to carry a battery, mount an antenna and operate easily in the field.

2) The G90 also needed a bit of protection from field abuse; so

3) A manpack configuration was designed that:

a) uses two vented clamshell case halves and four clamps to secure the radio between eight Sorbothane shock absorbing pads;

b) has a tray with hook and loop straps for securing a battery; and

c) provides an antenna mount for a whip antenna.

Disclaimer: Calling this a "manpack" is a bit of a euphemism. I'll be the first to admit that a true manpack is portable, has rechargeable batteries, is relatively impervious to dust and water, and rugged enough to take a licking and keep on ticking.

This ain't that. It does provide some protection and impact resistance without compromising cooling as a sealed enclosure might, and handles an antenna and internal battery. That's good enough to have a lot of fun.

The G90 Manpack

The first time I saw a G90, I knew that sooner or later I would buy one and try to make a self-contained portable grab and go rig with it.

20 watts is big, and like my favorite old FT-897. But the G90 is much lighter, has a better display, is easily converted to HF general coverage, and is a pretty respectable radio for the price. Like they say, IYKYK.

This is it.

The easiest way to unpack this is through pictures. The first shows the radio with its two clamshell halves opened up.

On the left, the bottom clamshell half carries the radio and battery, and on the right, the top clamshell half carries the four buckles that secure the halves together, the antenna feed-through, and the antenna bracket.

The Battery Tray

For reasons I can't explain, it took me quite some time to develop this relatively simple battery tray.

Working down from the top, you see a right-angled piece of metal - the battery tray- that has two large holes. These holes secure the tray to the bottom clamshell half, and secure the two hook and loop battery straps.

The battery tray was made to be removable, not to change the battery as much as to be able to change the tray to one that can hold larger or multiple batteries. This set up uses a 5800 milliamp hour generic battery, which is fine for a few hours in the park.

The assembled tray and battery looks like this.

If you look below, you can see how the bolts that secure the battery tray to the lower clamshell half also secure the ends of the hook and loop straps that overlap to secure the battery onto the tray.

One of the reasons it took a while to develop this tray was that I kept trying to use more complicated means to secure the battery. In the end using a couple of straps with sewn hook and loop portions was easy. Turns out that you can easily melt a mounting hole in a polymer strap by pushing a hot soldering iron through the strap. This makes a hole and melts the periphery of the hole in effect forming a nice, plastic built-in washer for the bolt to pass through, like this.

The Clamshell Halfs

Both the upper and lower clamshell halves are made from identical discarded cabinet pieces.

In this case (no pun intended), the halves are tops of discarded Mirage VHF amplifiers. The tops are flexible enough that the top half can be spread over the bottom half with some overlap.

The lower half looks like this.

The two large cutouts in the sidewall of the bottom half are there so that the screws that hold the hinges to the upper half can slide over the lower half without the screw heads on the top inner wall pushing the bottom wall inward.

This may make more sense if you look at a closeup of the clamps. These are eBay specials, mounted with 4-40 by 3/8 inch screws, with the heads on the inside and the nuts on the outside of the clamshell wall.

You often see clamps of this style used to secure battery cases to the bottom of military manpacks.

In this case, the clamps also serve to compress the clamshell halves together by squeezing the radio between shock-absorbing Sorbothane vibration damping pads.

Each clamshell half uses four one inch square Sorbothane pads for mounting and isolating the radio. If you want to know more about how Sorbothane works, look at their website. Basically, you need a calculated surface area for a given dimension and weight of radio, and the pads need to be in slight compression to work properly.

Sorbothane isolation pads are a bit pricey, so mine are cut from a sheet of 1/4 inch thick Sorbothane into one inch squares - much cheaper. The pads are secured to the clamshell with carpet tape. The Sorbothane can be purchased with adhesive on one side, but the carpet tape does a much better job of securing the pads than the manufacturer's adhesive IMHO.

So it's a happy coincidence that if the cabinet hinges are mounted properly, the pads (which are very grippy) will be properly compressed for vibration damping when the clamps are secured, and that compression traps the radio in the case without the use of further mechanical means. If you're uncomfortable with that, you can add an L-shaped bracket to the lower clamshell that captures the G90 ground screw, but I've found that unnecessary.

Using the pads also ensures that there is airflow across the radio heatsink. Look between the radio and the lower clamshell half in the picture below. You can see the light shining through a large gap formed by the pads between the radio and the case. This ensures that air can flow over the heatsink - something that would not happen if the radio was attached directly to the case.

This gets to the real point. You can pop the radio in and out of the case by releasing or securing the four clamps, and you don't need any extra fixtures added to the radio to do that.

BUT fitting the clamps and pads to get the right tension to keep the radio in place and have the clamps operate properly can be a PITA. At the very least, it requires careful experimentation, even more careful placement and drilling, and lots of testing to make sure the clamps remain closed and the radio remains secure.

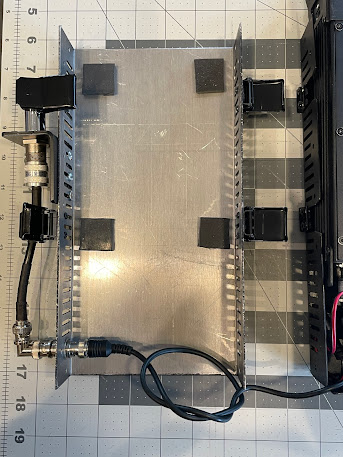

The top clamshell half carries the antenna hardware - the BNC pass-thru, the antenna bracket, and the feedline connecting the feed-thru to the antenna mount secured to the antenna mounting bracket. This half also includes four Sorbothane pads, all visible in the picture below.

As with the lower clamshell half, the pads are located approximately at the edges of the radio on a line with the hinges, to maximize the compressive effect of the hinges on the pads.

When the two halves are clamped together, the outside of the manpack, on the antenna side, looks like this.

Comments